Wet Cast Production Equipments

Wet-cast Production Equipment

FMS (Flexible Manufacturing System)

This sytem allows the concrete precast producer to pour almost any type of product using a flexible and underground lift carrier. This system is used for moving the forms from the stripping area to pouring area.

The FMS is installed level to the production floor allowing for a clean and safe environment.

L – Crane Pouring System

This is a pouring system that is used for large scale or heavy forms which which cannot be poured using the FMS (Flexible Manufacturing System).

The L-Crane System allows the use of minimal floor space for precast forms by manuvering overhead for filling of the forms.

Production efficiency can be greatly increased by including the use of the TMD (Toyota Monorail Distributor).

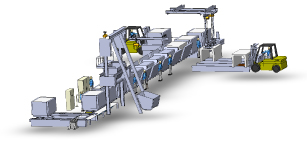

275 Production Line (Pushing Conveyer Line)

This line made it possible to produce huge quantities in high productivity for producing the products like roadside drains, kerb blocks, etc.

“275” means all the moulds moving on the line are all with the base pallet in the dimension of 550W X 2750L.

TMD (Toyota Monorail Distributor)

This sytem allows the concrete precast producer to pour almost any type of product using a flexible and underground lift carrier. This system is used for moving the forms from the stripping area to pouring area. The FMS is installed level to the production floor allowing for a clean and safe environment.